- Home

- Our Products

-

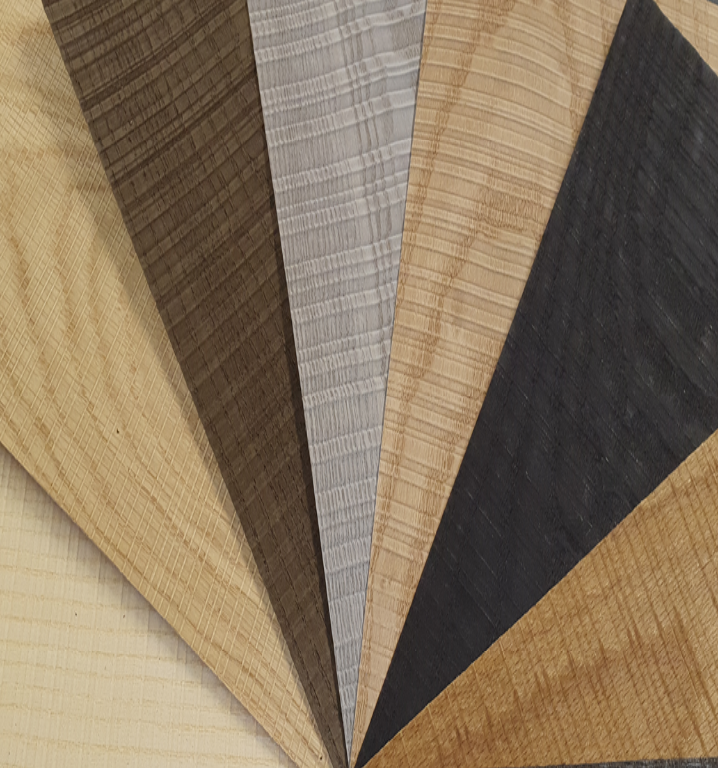

Veneer Range

Enhanced Veneer

Natural Veneer

We supply more than 200 varieties of natural veneer, ranging from everyday species like walnut, oak and ash, to rare exotic species such as pearl moon ebony, ziricote and spalted figured maple.

Browse natural veneersNatural veneer is a unique and beautiful material sliced from the log (flitch) of a tree. Each piece of veneer features an authentic pattern which is reflective of the species of tree it came from and environment, soil and climate where it has grown.

Logs are sliced in sequence and packaged into bundles containing 24 or 32 leaves or sheets. These bundles allow for consistency in the end product once spliced, pressed and lacquered. However the manufacturing process is designed so as not to alter or enhance the features of the wood and as such there will be some natural variation between different sheets of veneer.

The logs chosen for natural veneer production are carefully selected to ensure they are the highest quality. A veneer-grade log is the highest grade of any forest, representing only few percent of each woodland. The quality is important because the features of the wood will be visible in the finished product. Careful selection by our UV log buyers and strict adherence to FSC principles make our processing methods ecological and sustainable.

Once selected, logs delivered to the factory are cooked to make them supple for slicing. They are then cut into thin slices of veneer, which are dried, sorted and carefully inspected for defects. You can see more in our video:

Dyed Veneer

Dyed veneers are natural veneers which have been treated with high quality dye to create new shades of colour.

We stock more than 150 dyed veneers in our Spectrum range and able to develop and manufacture special bespoke finished colour to-order for your scale residential, commercial and hospitality projects.

Browse dyed veneersDying allows for new shades of wood to be created, including those which are not found in nature. In dying, a natural veneer maintains the grain, characteristics and beauty of the species core, while increasing consistency of colour.

Our dyed range avoids complicated sprays and difficult-to-replicate dyes, resulting in consistency of colour even across large sized projects. We work sequentially across sheets of veneer, treating each one both before and after the dying process to ensure the finished product is uniform in colour. The colour fastening properties and absorbability vary depending on the species chosen.

As with all veneer, UV prohibitors in the lacquer are recommended to increase the resistance of the wood to light. See our Terms and Conditions for more information.

Rivved Veneer

Rivved veneers - also known as textured or rough sawn veneer - are specially cut veneers which can be found in our Tinted range.

Browse textured veneersKnown as rivved, textured or rough sawn veneer, this process is where a specially grooved knife blade on the lathe is used and veneers are cut at an angle to provide a textured surface. This gives the veneer a unique look and feel, which can be felt even after veneer has been lacquered and pressed onto a board.

The colour of engineered veneer can change over time. UV prohibitors in the lacquer are recommended to increase the resistance of the wood to light. See our Terms and Conditions for more information.

Reconstituted Veneer

Engineered or reconstituted veneer is an alternative to natural veneer, providing authentic-looking, consistent design suitable for a variety of applications.

Combining natural veneer with state of the art manufacturing technologies, we produce high quality engineered veneers for use as decorative surfaces. All of our engineered veneers are handled, jointed and laid in the same way as natural veneers.

Browse engineered veneersEngineered veneer (EV) - also known as reconstituted veneer (Recon) or recomposed veneer (RV) - is a re-manufactured product. These veneers are real-wood and born from a natural core. The difference is the veneer in engineered though templates and pre-developed dye moulds. This means that typically engineered veneers will be more consistent in terms of appearance and colour - and will generally be free of surface knots and other natural characteristics found in each species, while still maintaining the natural wood grain from the core species used.

An engineered-grade log is harvested from fast-growing, renewable species of trees. The UV Group has always been dedicated to preserving our planet and the use of renewable species ensures our methods are sustainable Logs to be used for engineered veneer production are thinly sliced, dyed in vats and glued into blocks. The use of fast-growing trees means engineered veneers can often (but not always) be lower cost than natural veneers.

Smoked Veneer

Fumed veneers are exposed to Ammonia Oxide and Silver Nitrate which enhance and change the natural tanins of the wood.

The chemical reaction permanently changes the colour of the natural veneer, darkening the wood and makes them less resistent to colour change.

Browse fumed veneersChemical enhancement - such as fuming, silver or thermo-treatment - uses a chemical reaction to darken the wood, creating a sophisticated looking end product. Through the over exposure of chemicals - ammonia oxide, silver nitrate and others - for a defined period of time, the natural tannins in the veneer react to create a look which is permenant and irreversable.

The change can be significant. White Oak is typically a white or biscuit colour prior to the fuming process whereas post the chemical reaction, the wood colour can be described as a Milk Rich Teak, Pecan-Nut Brown, Dark Ground Coffee or Black Forest.